"We are living through a third digital revolution," declares MIT's Neil Gershenfeld, "and this time it's in fabrication." Just as digital communication replaced analog phones with the internet, and digital computation evolved from room-sized mainframes to pocket-sized smartphones, digital fabrication is now transforming how we make things-from mass production to personal creation.

In India, this revolution is unfolding dramatically. With 10,000+ Atal Tinkering Labs established across 722 districts and 2,500+ fab labs operating globally, we're witnessing the democratization of manufacturing itself. For Makerspace Masters and educational institutions, understanding this transformation isn't optional-it's essential for preparing students for a world where anyone can make (almost) anything.

Understanding the Third Digital Revolution: From Mass to Personal Manufacturing

The Three Waves of Digital Transformation

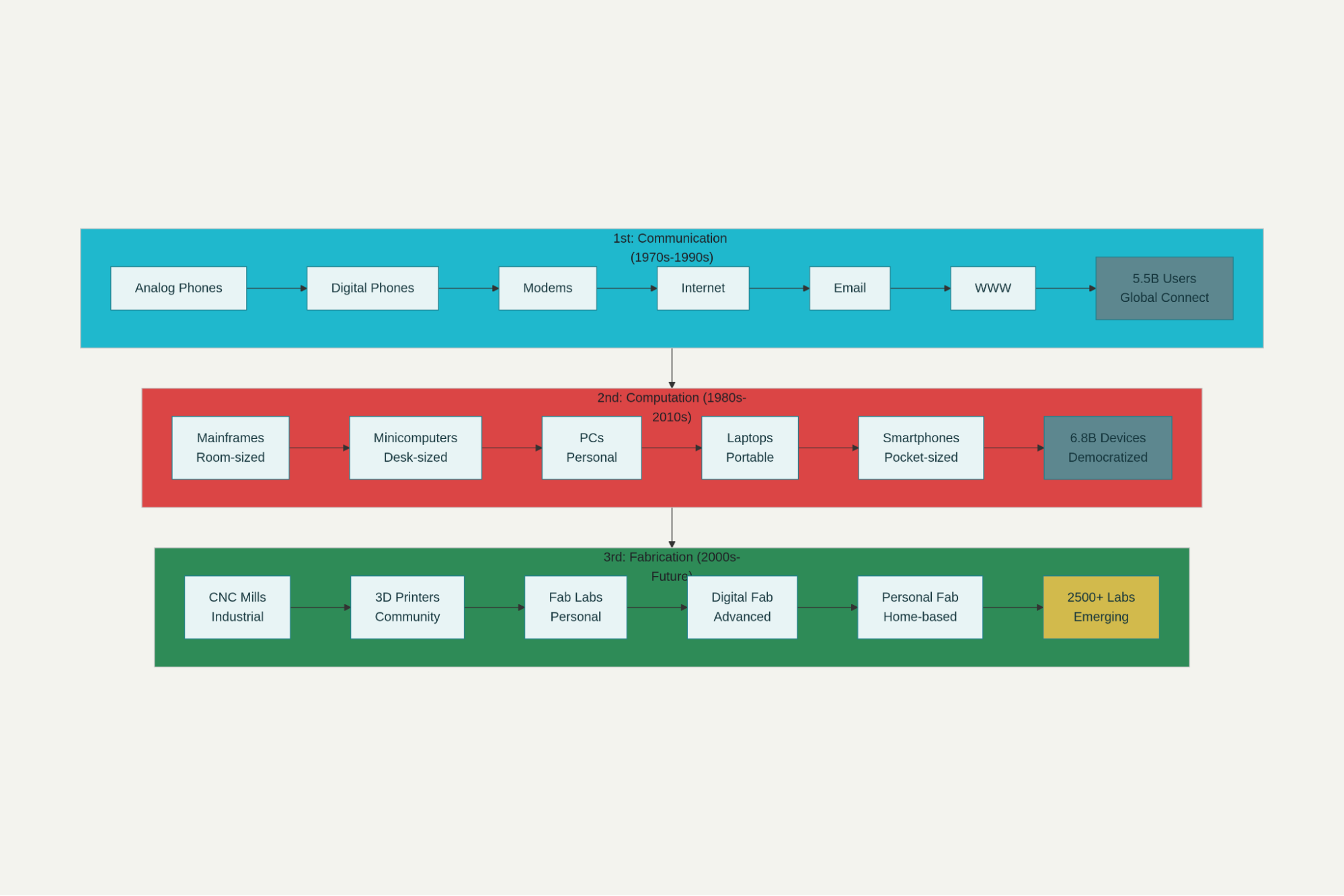

Neil Gershenfeld's groundbreaking book "Designing Reality: How to Survive and Thrive in the Third Digital Revolution" maps our technological evolution through three distinct phases. Each revolution followed the same pattern: moving from analog to digital, from institutional to personal scale, and from scarcity to abundance.

The First Digital Revolution-Communication transformed how we connect. Analog telephone calls degraded with distance, but digitizing communications allowed errors to be detected and corrected, leading to the Internet. Today, 5.5 billion people carry smartphones, accessing instantaneous global communication that was unimaginable just decades ago.

The Second Digital Revolution-Communication changed how we process information. Analog computations degraded with time, but digitizing computing enabled error correction, leading to microprocessors and personal computers. What once required room-sized mainframes now fits in our pockets, with 6.8 billion connected devices worldwide.

The Third Digital Revolution-Fabrication is transforming how we make things. Manufacturing today remains analog-although designs are digital, the processes are not. This revolution promises to digitize not just the description of a design but also the materials it's made from, similar to how living systems assemble from amino acids.

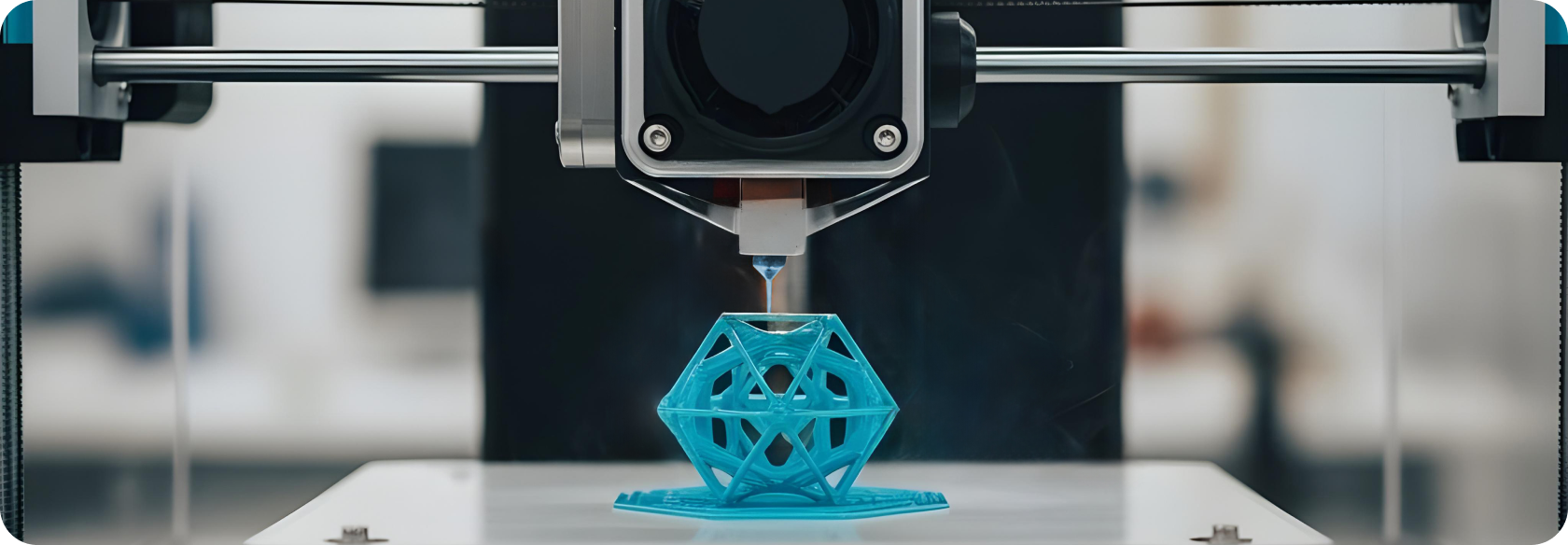

Digital Fabrication: Beyond 3D Printing Hype

While media attention focuses on 3D printing, true digital fabrication encompasses much more. As Gershenfeld explains, "3D printing is to digital fabrication what the microwave was in the 1970s to the kitchen of the future-just one product". A complete fab lab includes:

- Computer-controlled laser cutters for precision material processing.

- 3D scanners and printers for digital-to-physical conversion.

- Numerically-controlled milling machines for subtractive manufacturing.

- Surface-mount electronics production for embedded systems.

- Programming tools for low-cost embedded processors.

- Design and collaboration software connecting global maker networks.

The goal isn't replacing mass manufacturing but complementing it with personalized, local production. As Gershenfeld notes: "Mass manufacturing will still stay, but it will by definition make the boring stuff because everyone gets the same thing".

India's Fabrication Revolution: From Jugaad to Digital Making

The Fab Lab Movement Takes Root

India's maker movement began in the early 2010s, built upon the country's traditional "jugaad" culture of frugal innovation. Vigyan Ashram in Pune, recognized as India's first fab lab, introduced learning-by-doing principles long before the global maker movement gained momentum.

The transformation accelerated dramatically with government support. The Atal Innovation Mission, launched in 2016, established 10,000 Atal Tinkering Labs across Indian schools. This represents one of the world's most comprehensive attempts to integrate practical learning and innovation into traditional education systems.

Success Stories: Indian Fab Labs Making Impact

FabLab Nagpur exemplifies India's fabrication revolution. Established in 2018 as India's first self-sustaining makerspace, it addressed over 15 distinct COVID-19 challenges, developing everything from PPE to healthcare devices. Their innovations include:

- LoRa-based wagon door detection systems for Central Railways.

- Bamboo charcoal-based purification systems for mucormycosis treatment.

- Algae cultivation plants developed for IIT Bombay.

- 10 TPD animal feed production systems using cotton stalks

FabLab Kerala, backed by the state government through Kerala Startup Mission, demonstrates how policy support accelerates innovation. Their projects range from respiratory apparatus for COVID-19 patients to gesture-sensing digital alarm clocks.

The scale is impressive: 1.2 crore+ students are actively engaged in Atal Tinkering Labs nationwide, representing unprecedented reach in hands-on education.

AICTE IDEA Labs: Scaling Digital Fabrication in Higher Education

The All India Council for Technical Education launched the IDEA Lab network in 2021, extending digital fabrication into engineering colleges nationwide. D.Y. Patil International University pioneered cost-effective fab lab setups using locally manufactured equipment, reducing costs by 70-80% while maintaining functionality.

Dr. Anil Sahasrabudhe's vision for integrating digital fabrication across India's technical education system is revolutionary. By training faculty through intensive programs and establishing equipment networks, the initiative is creating "digital fabrication fever" expected to spread widely across the country.

The Educational Transformation: From Theory to Making

Reshaping Learning Through Fabrication

Digital fabrication fundamentally changes educational paradigms. Instead of passive consumption of information, students become active creators solving real-world problems. Research consistently shows that maker-centered learning improves student attitudes toward STEM subjects, with particularly strong effects on students with initially high or low self-efficacy levels.

Innovation labs are not just equipped rooms—they're ecosystems of creativity and learning. These spaces provide:

- Collaborative learning environments where students share diverse perspectives

- Project-based learning with tangible, real-world applications

- Mentorship programs connecting students with industry professionals

- Competition opportunities motivating creative boundary-pushing

Skills for the Future Economy

The third digital revolution demands new competencies beyond traditional academic subjects. Students in digital fabrication programs develop:

- Technical Skills: 3D modeling, electronic circuit design, programming embedded systems, operating CNC machines, understanding material properties and manufacturing processes.

- Design Thinking: Systematic approaches to problem-solving emphasizing empathy, ideation, prototyping, and iteration.

- Collaboration Abilities: Working effectively in interdisciplinary teams, communicating ideas across domains, leveraging diverse perspectives.

- Innovation Mindsets: Comfort with ambiguity, resilience in failure, willingness to experiment and iterate.

Global Context: Learning from Fab Lab Pioneers

MIT's Fab Academy: The Gold Standard

The Fab Academy, developed by Neil Gershenfeld, represents the most comprehensive digital fabrication education program globally. This 20-week intensive course connects 75+ fab labs worldwide, training participants to become fluent in digital fabrication technologies.

Each week focuses on specific techniques: computer-controlled cutting, electronics production, 3D scanning and printing, electronics design, computer-controlled machining, embedded programming, molding and casting, input devices, output devices, applications and implications, networking and communications, and machine building.

The program culminates in personal projects incorporating at least five learned techniques, documented online and reviewed by global mentors. Graduates join a close-knit community of fab labs worldwide, becoming part of a global innovation network.

Fab City Initiative: Urban Manufacturing Revolution

The Fab City movement, launched at Barcelona's Fab Summit in 2013, represents digital fabrication's urban-scale potential. Barcelona committed to producing everything it consumes within 40 years, with similar commitments from 49 cities and regions globally, including Boston, Cambridge, and Somerville.

This vision of localized production addresses multiple challenges: reduced transportation costs, customized products meeting local needs, resilient supply chains, and sustainable manufacturing practices.

The Future of Making: Personal Fabricators and Beyond

The Roadmap to Universal Fabrication

Gershenfeld's vision extends far beyond current fab labs to personal fabricators—integrated units making everything. The progression mirrors computing evolution:

- Current fab labs = minicomputers (institutional scale, $100K investment)

- Emerging maker tools = hobbyist computers (personal scale, $10K investment)

- Future personal fabricators = integrated PCs (consumer scale, $1K investment)

- Ultimate goal = Star Trek replicators (universal assembly)

Research at MIT's Center for Bits and Atoms focuses on "machines making machines"—tools that can reproduce themselves. This capability would enable democratic and viral technology spread, where communities don't just use fabrication tools but create them locally.

Implications for Education and Society

The third digital revolution will profoundly impact how we live, work, and learn. For education, implications include:

- Curriculum Integration: Digital fabrication won't remain separate but will integrate with traditional subjects—mathematics through geometric prototyping, science through hypothesis testing, language arts through design communication.

- Assessment Transformation: Moving from standardized testing toward portfolio-based evaluation of actual innovations and problem-solving capabilities.

- Global Collaboration: Students worldwide collaborating on shared challenges, learning from diverse cultural perspectives and approaches.

- Local Problem-Solving: Educational projects addressing community needs, creating immediate social impact while developing skills.

Makerspace Masters: Architecting India's Fabrication Future

Bridging Global Vision with Local Implementation

For Makerspace Masters, the third digital revolution represents unprecedented opportunity to position Indian education at the forefront of global transformation. Our approach recognizes that successful implementation requires more than equipment—it demands systematic integration of space design, curriculum development, teacher training, and community engagement.

Our comprehensive ecosystem includes:

- Masters (Core K-12 Innovation Labs): State-of-the-art makerspaces transforming passive learners into confident creators, aligned with NEP 2020 and CBSE requirements.

- Masters+ (Franchise Model): Scalable innovation hubs backed by proven methodologies, enabling rapid deployment across India's educational landscape.

- MastersX (Incubation Ecosystems): Advanced environments where student ideas evolve into market-ready ventures through structured innovation methodologies.

- Masters Community (Global Network): Connection to international maker communities, ensuring Indian students participate in global innovation conversations.

The Competitive Advantage

Schools implementing comprehensive digital fabrication programs position themselves strategically for the future. As the number of fab labs doubles every 18 months globally, institutions must evolve from traditional teaching toward active making environments.

The choice is clear: lead India's fabrication revolution or risk obsolescence as student expectations and economic demands shift toward innovation-based learning.

Looking Forward: Making the Future

Neil Gershenfeld's third digital revolution isn't a distant possibility—it's happening now. With 2,500+ fab labs operating globally and India's 10,000+ ATLs reaching 1.2 crore students, we're witnessing the early stages of manufacturing's transformation from mass production to personal fabrication.

For educators, parents, and policymakers, the message is urgent: The students learning in today's innovation labs will shape tomorrow's economy. Those equipped with digital fabrication skills won't just participate in the future—they'll create it.

The revolution has begun. The question isn't whether digital fabrication will transform education—it's whether your institution will lead or follow this transformation.

Ready to architect your institution's role in the third digital revolution? Discover how Makerspace Masters designs comprehensive fabrication ecosystems that prepare students not just for the future of work, but for the future of making.